Electrolysis lines

1 | Electrolysis

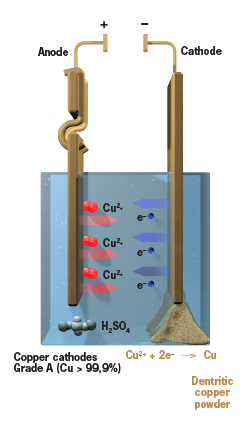

By electrolysis we produce dendritic copper powders: Thereby due to process parameters and preparation we can offer a wide range of different grades from light apparent density (AD) (0,7 g/cm3) up tp heavy grades (3,0 g/cm3).

Washing Process and Drying

2 | Washing Process and Drying

Important for good quality of the powder is the treatment after electrolysis., e.g. washing process and drying.

Hereby we use highly sophisticated process techniques which have been mostly developed inhouse. Steady process control and process development enables us to keep production at its most modern and efficient.

Homogenisation and QC

3 | Homogenisation and QC

Blending and homogenisation in double-cone blenders and strict quality control guarantee constant superior quality of our products. Due to customer related testing plans we can adjust the products exactly to the needs of each customer.

Shipment only can take place after ok from quality control (supported by SAP-system).

With this we fulfil the strict demands for certification (ISO 9001, TS 16949) for the benefit of our customers.